Flat machining

On our flat processing machines, we process steel, galvanized steel, stainless steel and aluminium in thicknesses from 1 to 25 mm and in dimensions up to 2000 x 4000 mm.

We produce using fully automated plants (lasers, punching, deburring, finishing) and guarantee high capacity and fastest throughput times. Our well stocked warehouse offers everything you could need.

Lasers

We have extensive experience in the field of sheet metal with a focus on laser cutting and punching. Sheet metal parts are cut or punched; if desired, also deburred and delivered ready for installation..

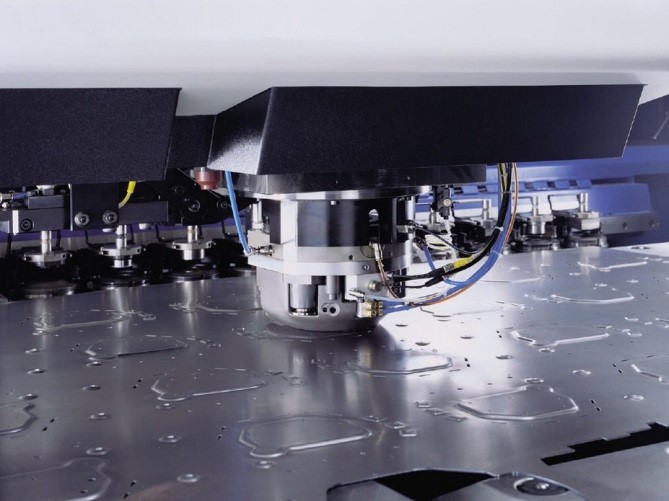

Laser cutting

We use laser cutting in those cases where precise and fast processing with high flexibility in terms of shaping is required. Our laser cutting machine is suitable for sheet thicknesses from 0.5 mm to 25 mm. Compared to alternative processes, such as punching, laser cutting can already be used economically for small batch sizes.

A large machine park guarantees high capacity and thus short delivery times

Punching

The interaction between punching and laser machines enables versatile processing. This enables us to produce your series parts in shifts on schedule and at low cost.

Thanks to state-of-the-art machines, processes such as forming, countersinking, embossing or thread cutting are possible in one process step.

Scratch-free punching and laser cutting also eliminates the need for time-consuming post-processing.

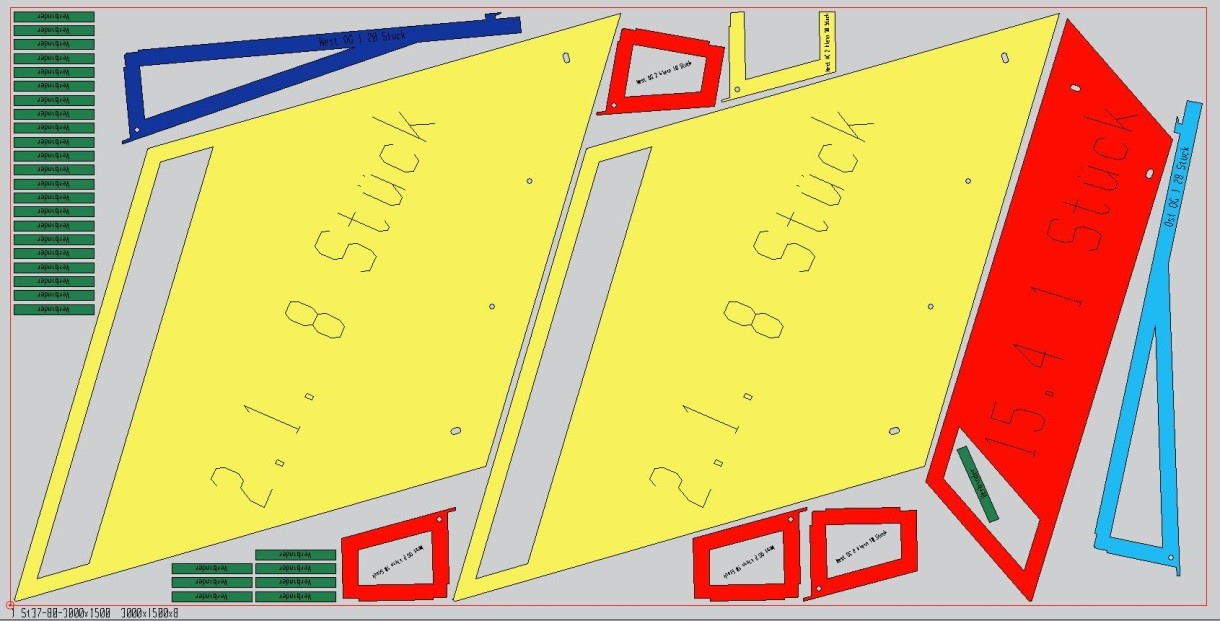

Programming

We attach great importance to an economic and efficient nesting of orders. Sheets are used optimally; this saves material and reduces costs.

Deburring

Our multi-rotation brush machines deliver absolutely uniform deburring, rounding and finishing of previously laser-cut, punched, milled or profiled workpieces. This puts us in a position to meet the high demands of customers in the medical technology sector.

Parts cleaning

The new alkaline cleaning and degreasing plant cleans sheet metal parts deep in the pores, gently and quickly. We supply ready-to-install CrNi sheet metal parts for all applications.